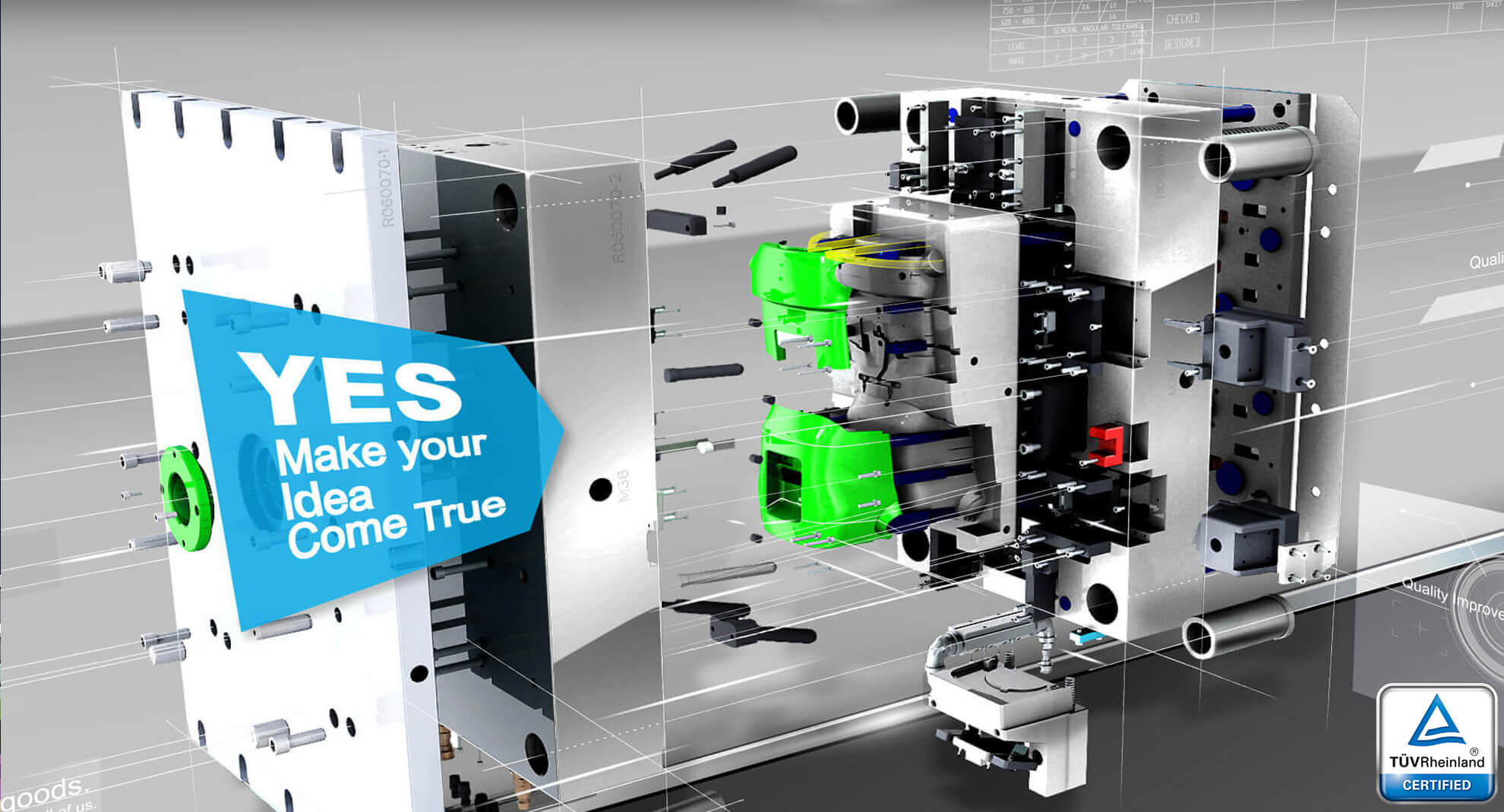

Moldes de Plástico, Moldeo por Inyección de Plástico, Moldes de Caucho de Silicona, Moldes de Caucho de Silicona Líquida, Matrices de Estampado Metálicas

Con más de 25 años de experiencia en el sector, Intertech Machinery Inc. utiliza una tecnología de producción muy perfeccionada para producir una variedad de moldes en Taiwán.

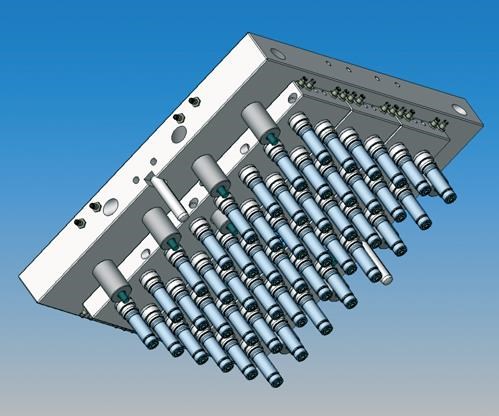

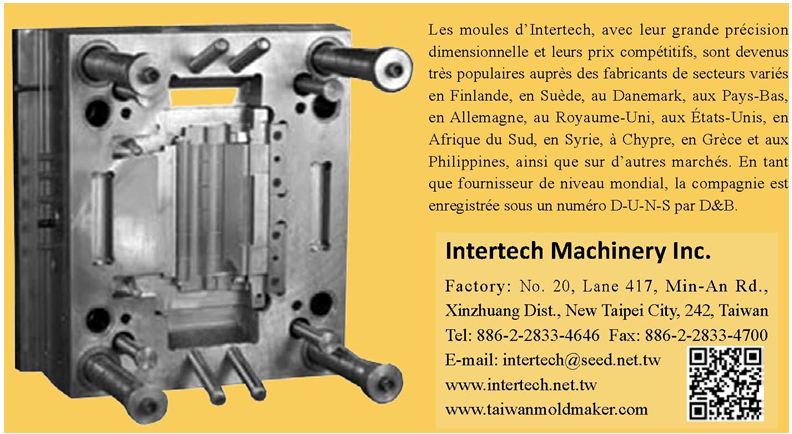

La línea de productos de la compañía abarca una amplia gama de moldes de plástico, moldeo por inyección de plástico, moldes de caucho de silicona, moldes de caucho de silicona líquida y matrices de estampado metálicas. La compañía también está especializada en fabricar moldes socavados / moldes de desenroscar / moldes de núcleo extraído / moldes pulidos brillantes PMMA/PC / moldes de núcleo intercambiables / moldes de compresión calientes / moldes de inyección de 2 componentes / moldes piloto.

Intertech es muy profesional fabricando moldes y proyectos de moldeo en POM, componentes de ingeniería de Nailon+FG / productos médicos autorizados de PC, LSR , RoHS / tetinas para bebés de LSR / equipos de iluminación LED de PC, PMMA / piezas de automóviles de ABS, PP / productos electrónicos de ABS, PP / electrodomésticos de PP, PE, ABS / tapas de envase, cierres, recipientes de PP, PE / instalación de tuberías de PVC, PP, etc.

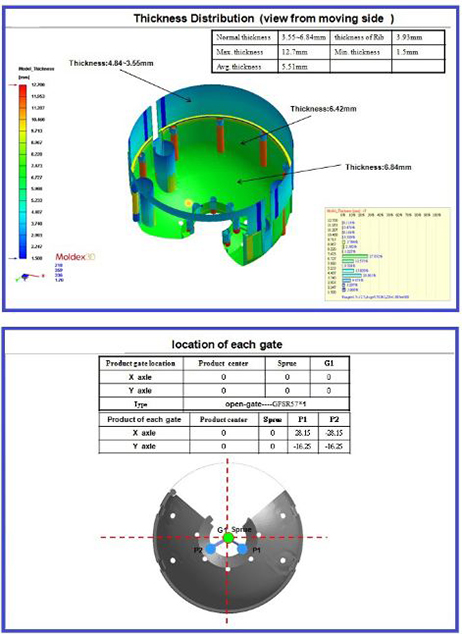

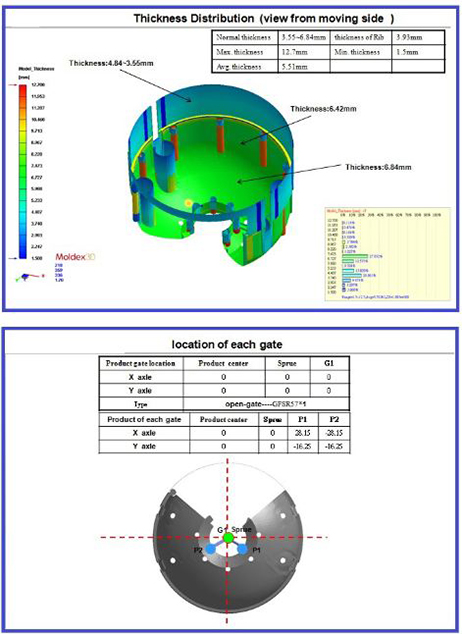

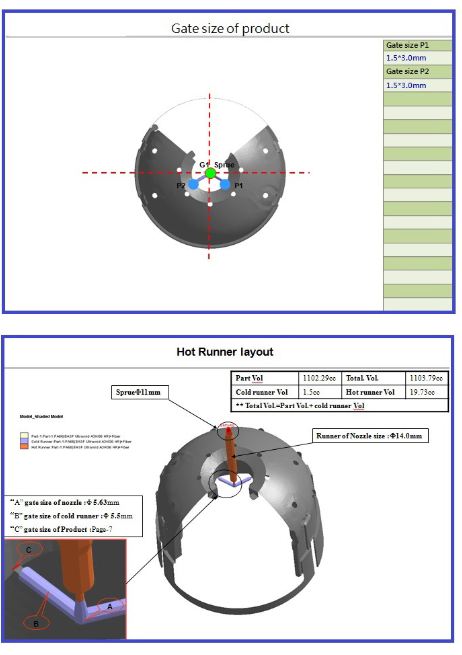

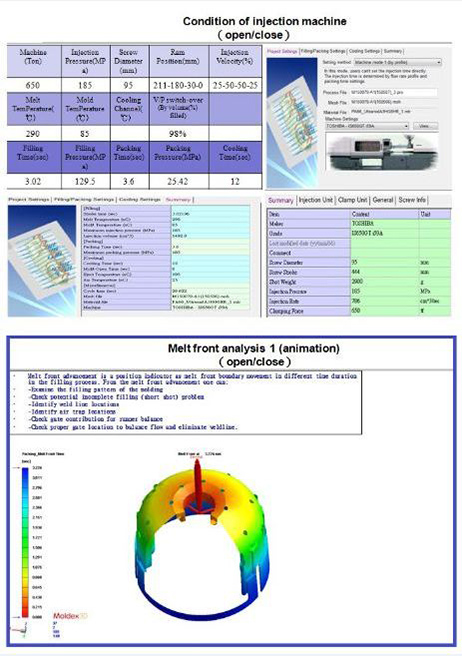

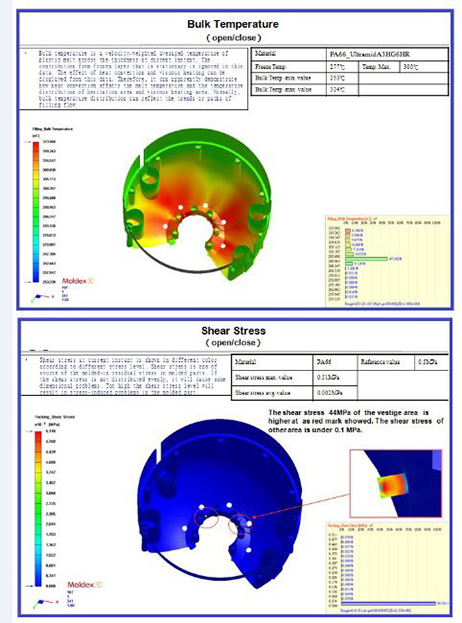

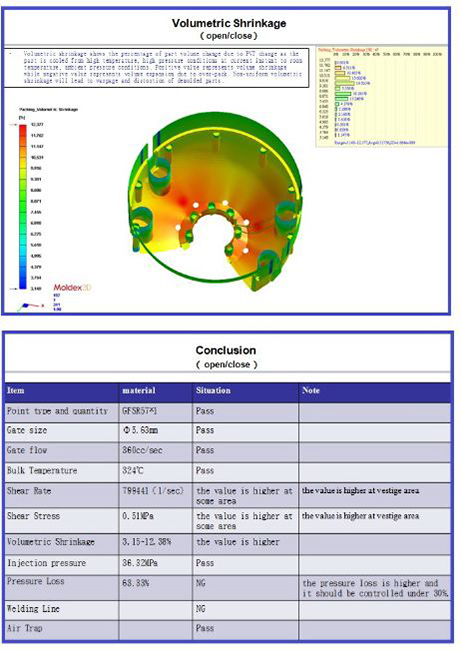

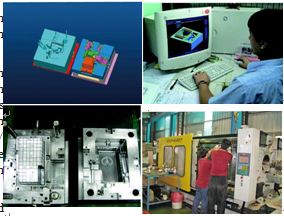

La excelente capacidad de ingeniería con software profesional CAD y CAM, como AutoCAD, Pro-E, Cimetron, I- DEAS, y Análisis de Flujo de Moldeo, en el trabajo de I+D permite a Intertech ofrecer a los clientes más exigentes eficiencia, procesos de producción de ciclo completo, desde el diseño y prototipos de moldes hasta la fabricación y montaje a precios muy económicos, junto con oportunos asesoramientos, resolución de problemas, y servicios posventa.

Los moldes de la compañía, con su excelente precisión dimensional y precios competitivos, ha demostrado ser muy popular entre los fabricantes de diferentes sectores en Finlandia, Suecia, Dinamarca, Países Bajos, Alemania, Reino Unido, EE.UU., Sudáfrica, Siria, Chipre, Grecia y Filipinas, así como otros mercados. Como un proveedor de clase mundial, la compañía ha sido registrada por D&B D-U-N-S.

Intertech Machinery Inc.

Factory: No. 20, Lane 417, Min-An Rd., Xinzhuang Dist., New Taipei City, 242, Taiwan

Tel: 886-2-2833-4646 Fax: 886-2-2833-4700

E-mail: intertech@seed-net.tw

http://www.intertech.net.tw

http://www.taiwanmoldmaker.com